The US Air Force airborne laser, (ABL), designated YAL-1A, is a high-energy laser weapon system for the destruction of tactical theatre ballistic missiles, which is carried on a modified Boeing 747-400F freighter aircraft.

The ABL is being developed by the Air Force Research Laboratory and Team ABL, comprising Boeing, TRW (now Northrop Grumman Space Technologies) and Lockheed Martin.

Boeing is responsible for programme management, systems integration, battle management system and modification of the 747-400F aircraft. TRW is building the laser systems.

Lockheed Martin Space Systems is responsible for the target acquisition and beam control systems.

The US Missile Defense Agency (previously called the Ballistic Missile Defence Organisation) is responsible for the management of the programme and it is executed by the USAF from Kirtland AFB in Albuquerque, New Mexico.

The requirement of 10 to 20 modified Boeing 747s, at $1.5bn apiece, and $100m investment a year had made the maintenance of the ABL YAL 1A not operationally viable, making the US Air Force to stop raising funds for the laser. The US Government has spent approximately $5.2bn on the ABL YAL 1A project till February 2011.

Airborne laser system development

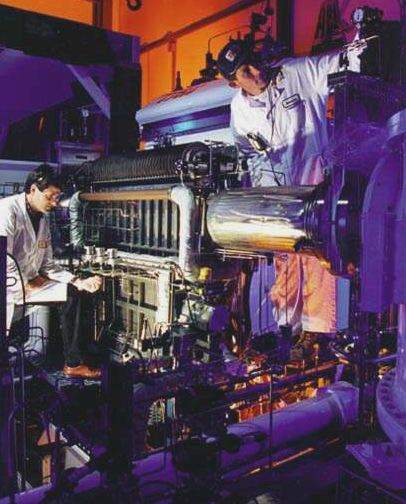

In 1996, the Department of Defense awarded Team ABL a $1.1bn Programme Definition and Risk Reduction (PDRR) contract for the development and test of an airborne laser weapon system. During tests at TRW’s Capistrano test site in 1998, the laser demonstration module achieved a power level 10% higher than the requirement. In April 2000 the ABL final critical design review was completed.

Modification of the aircraft, involving installation of the turret in the aircraft’s nose and modifications to accept the laser, optics and computer hardware, was completed in May 2002.

In July 2002, the modified aircraft took the first of a series of test flights. After receiving airworthiness certification, the aircraft was flown to Edwards Air Force Base, California, in December 2002, for the installation of systems. The aircraft returned to airworthiness flight testing in December 2004 following installation of the beam control / fire control system.

In November 2004, all six modules of the COIL laser were successfully fired for the first time. In August 2005, the ABL completed a series of flight tests demonstrating the performance of the beam and flight control systems. The BILL laser was delivered in January 2006.

Airborne laser system flight and firing tests

In February 2007, the ABL began a series of flight tests, which included the first in-flight firing of the TILL targeting laser at a simulated target, in March 2007.

This was followed by flight tests of the BILL illuminating laser and tests of TILL, BILL and a surrogate high-energy laser (SHEL) low-power laser. Installation of the six COIL laser modules was completed in February 2008. The first firing (‘first light’) of the COIL laser took place in September 2008. The test lasted less than a second and was followed by further ground tests of increased duration and power. In November 2008, the COIL laser was fired and focused through the beam control / fire control system.

A high energy laser aboard the aircraft was successfully fired from the Edwards Air Force Base in August 2009. The YAL 1A laser travels at the speed of light to destroy ballistic missiles in their boost phase of flight.

In January 2010, the high energy laser was fired to intercept a test Missile Alternative Range Target Instrument (MARTI).

In February 2010, the US MDA and Boeing jointly tested the speed, precision and breakthrough potential of directed energy weapons deployed in the ABL test bed.

ABL COIL laser missile interceptor system

The ABL aircraft carries the COIL laser which generates the killer laser beam, an infrared surveillance and high speed target acquisition system and a high precision laser target tracking beam control system.

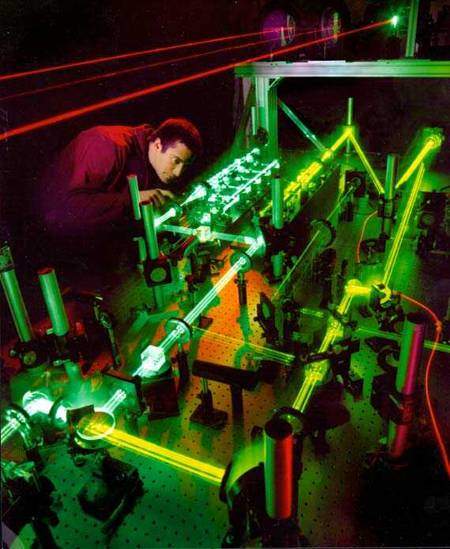

The laser weapon uses three laser beam systems: the powerful killing laser beam or primary beam, a set of illuminating laser beams and a beacon laser.

The primary laser beam is generated by a megawatt chemical oxygen iodine laser (COIL) located at the rear of the fuselage, which lases at 1.315 micron wavelength. The high-power laser beam travels towards the front of the aircraft through a pipe. The pipe passes through a Station 1000 bulkhead / airlock, which separates the rear fuselage from the forward cabins. The high-power beam passes through the fine beam control system mounted on a vibration isolated optical bench. Beam pointing is achieved with very fast, lightweight steering mirrors, which are tilted to follow the target missile.

ABL TILL laser tracking system

A low-power, multiple beam, track illuminating laser (TILL), being developed by Raytheon Electronic Systems, is used to determine the target’s range and provides initial information on the atmosphere through which the beam is being transmitted. The illuminating laser tracks the target and provides aiming data for the primary beam.

The beacon illuminating laser (BILL) has been developed by Northrop Grumman Space Technology. The kilowatt class BILL reflects light from the target to provide data on the rapidly changing characteristics of the atmosphere along the path of the laser beam. This data is used to control a set of deformable mirrors in the beam control system. The mirrors introduce tailored distortions into the COIL laser beam to compensate for atmospheric distortions and allow the COIL laser beam to fall on the target.

Anti-balistic missile airborne laser system

The ABL is designed to detect and destroy theatre ballistic missiles in the powered boost phase of flight immediately after missile launch while the aircraft loiters at an altitude of 40,000ft.

Missile launch is detected by a reconnaissance system such as satellite or airborne warning and control system (AWACS) aircraft and threat data is transmitted to the ABL aircraft by Link 16 communications.

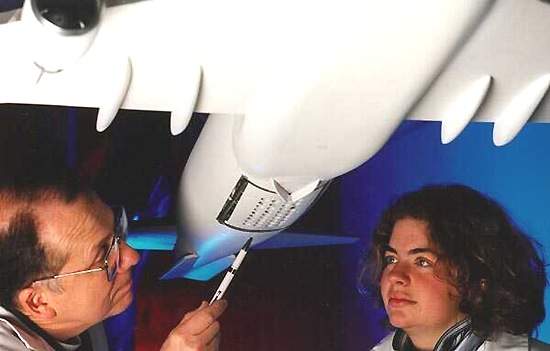

A suite of infrared, wide-field telescopes installed along the length of the aircraft’s fuselage detects the missile plume at ranges up to several hundred kilometres.

The pointing and tracking system tracks the missile and provides launch and predicted impact locations. The turret at the nose of the aircraft swivels towards the target and a 1.5m telescope mirror system inside the nose focuses the laser beam onto the missile. The laser beam locks onto the missile, which is destroyed near its launch area within seconds of lock-on.

Where the missile carries liquid fuel, the laser can heat a spot on the missile’s fuel tank, causing an increase in internal pressure resulting in catastrophic failure. Alternatively, the missile is heated in an arc around its circumference and crumples under atmospheric drag force or its own g-force.

The Global Missiles & Missile Defence Systems Market 2011-2021

This project forms part of our recent analysis and forecasts of the global Missiles & Missile Defence Systems market available from our business information platform Strategic Defence Intelligence. For more information click here or contact us: EMEA: +44 20 7936 6783; Americas: +1 415 439 4914; Asia Pacific: +61 2 9947 9709 or via email.