Defiant X: The Next Generation of High-Speed Military Helicopters

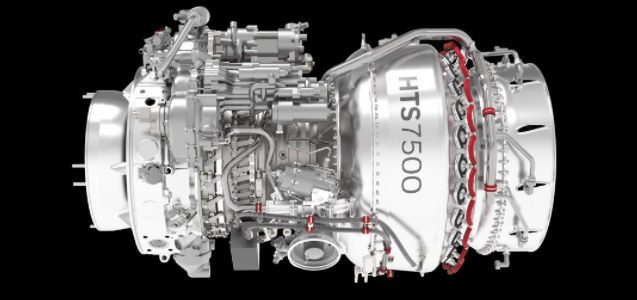

Lockheed Martin Sikorsky-Boeing selected Phoenix-based Honeywell Aerospace to provide its new HTS7500 turboshaft engine as the power behind the DEFIANT X helicopter. The 7,500shp engine is the latest model in the Honeywell family of military engines. The company produced the T55 engine for the iconic Boeing CH-47 Chinook helicopter too.

The new engine comes equipped with a modernized control system, which enables a highly secure flow of engine data. The control system improves operating capabilities, reduces life-cycle costs, and ensures engine health status through its digital thread road map.

DEFIANT X helicopter is in contest with Bell’s V-280 Valor tiltrotor aircraft in the US Army’s Future Long-Range Assault Aircraft (FLRAA) bid. The Army is set to choose a winner in the third quarter of 2022 (financial year or FY), and based on the FY21 budget justification document, the FLRAA prototype deliveries are scheduled for the second quarter of FY 2025.

The contenders are required to conduct preliminary analysis for special operations command, including for medical evacuation and features that will enable the exportation of the aircraft. Honeywell says that when compared to T55-714A, the HTS7500 has a 42% power improvement, a 18% reduction in specific fuel consumption and the lowest acquisition and lifecycle cots.

We talk to Honeywell Aerospace engines and power systems president Dave Marinick about the DEFIANT X’s engine.

Norbert Neumann: How important is the DEFIANT X project is to Honeywell?

Dave Marinick: Honeywell is very proud of our strong and sustained relationship with US Army Aviation. The T53 for the UH-1 Huey and the T55 for the CH-47 Chinook are two of the Army’s earliest turbine-powered helicopters, and we continue to provide the new T55 production engines for today’s Chinook platform.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe HTS7500-powered Sikorsky-Boeing DEFIANT X allows us to continue that tradition of reliable power and low operational cost for the next 60-plus years. The DEFIANT X is expected to provide sustained long-term growth for Honeywell with thousands of our engines to be delivered in the decades to come.

How were the following achieved: 42% more power, 18% fuel reduction and lower weight than the latest T55 model?

Honeywell has continually invested in turbine engine technologies that are being applied in the HTS7500. These come across a spectrum of design tools and methodologies, materials, and manufacturing technologies.

Many of these advancements are carried over from Honeywell’s successful business aviation engine lines, such as the HTF7000. We are also applying learnings and best practices from our collaboration with the US Army on Improved Turbine Engine Power (ITEP). Combined, they provide the foundation for the HTS7500 design — which achieves these power and fuel burn improvements.

How are low acquisition, maintenance and lifecycle costs achieved?

The architecture for the HTS7500 has its roots in the T55 family of engines which have been powering the Boeing CH-47 Chinook for over 60 years. That longevity enables a significant knowledge base through interactions with Boeing and US Army maintainers regarding critical reliability and replacement factors, user experience and maintenance practices.

We overlayed that breadth and depth of knowledge with the specific aircraft and mission requirements to develop the HTS7500 configuration specifically to meet the DEFIANT X aircraft and mission needs. The engine design includes a reduced part count, using proven, low-cost materials and lower turbine temperatures, which in turn minimizes cooling and sand glassing risk. All of these features inherently drive increased reliability and lower the cost.

In addition, low operational and support costs are achieved through this increased reliability and on-condition maintenance, supported by advanced engine health monitoring and a modernized control system that leverages Digital Thread and on-wing optimization from commercial engines.

The DEFIANT X has a dual coaxial rotor system and a push prop with clutch; do these change anything significant in terms of the engine design (in comparison with a Chinook CH-47 engine, for instance)?

We worked closely with the Sikorsky-Boeing team to understand their requirements, and intentionally designed the HTS7500 to specifically maximize the DEFIANT X aircraft and mission performance. By focusing on the DEFIANT X’s specific needs, we were able to optimize the cycle for a favourable power-to-weight ratio, lower turbine temperatures for increased reliability, while driving maintainability into the design by leveraging knowledge gained through years of collaboration with Army maintainers and Boeing. The modernized control system operates to optimize the engine cycles’ performance under varying conditions.

Is there anything else you’d like to add?

We’re committed to the US Army’s focus on modernization and multidomain operations, and the selection of Honeywell’s latest engine technology for the DEFIANT X is proof of that commitment. The HTS7500 checks all the right boxes for the Sikorsky-Boeing team and the Army, and we are excited to play a part in the future of vertical lift for our Army customer and Team DEFIANT.