GKN Aerospace will continue to support Gripen RM12 engines, as part of a three-year contract extension signed with the Swedish Defense Materiel Administration (FMV).

Valued at more than $175m, the contract covers technical product support, maintenance and parts supply for the RM12 engines on the Gripen fighter aircraft fleet in Sweden.

The performance based logistics (PBL) contract extension will run until the end of 2020.

GKN Aerospace Engine Systems CEO Mike McCann said: “GKN Aerospace is proud of our long-term support for Swedish Fighter aircraft and we appreciate that the FMV has extended the RM12 PBL-contract.

“GKN is looking forward to continuing to work together with the Swedish Armed Forces and the FMV and to further develop our relationship.

"We recognise and appreciate the continued confidence that the FMV has demonstrated in our team in placing this contract extension with us.”

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataWork under the contract will be carried out at the company's facility in Trollhattan, Sweden.

In addition to the Swedish Air Force, the Gripen fighters are flown by Hungary, Czech Republic and Thailand.

Built by Saab, Gripen is a multirole fighter jet that is capable of performing air-to-air, air-to-surface and reconnaissance missions.

To date, RM12 engine fleet has recorded close to 250,000 flight hours without any engine related serious incidents for the Gripen fighter aircraft, GKN said in a statement.

GKN Aerospace has been supplying fighter engines to the Swedish Armed forces since 1930.

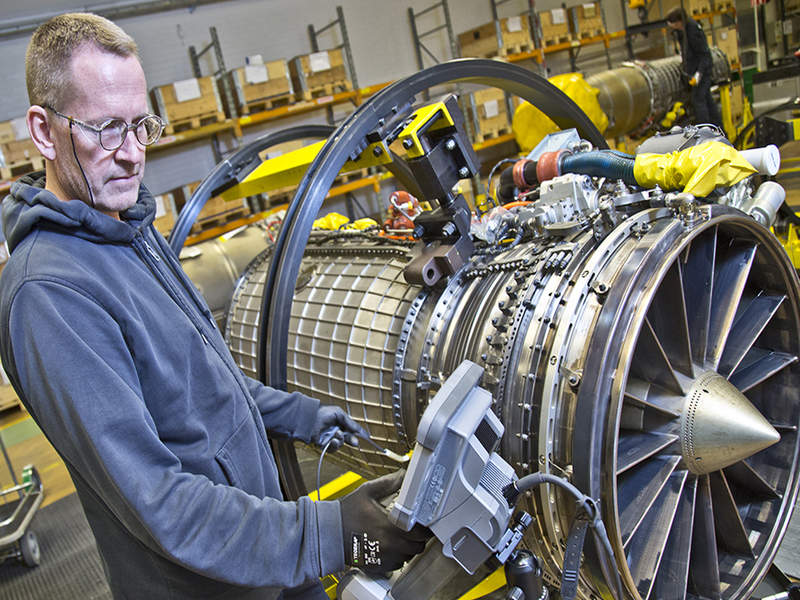

Image: A RM12 Engine engineer performing boroscope testing on the fan / compressor blades. Photo: courtesy of GKN Aerospace.