NUCAP Industries, Inc., the global innovation company widely known as a producer of braking system components, recently announced the creation of its new division, NUCAP Energy.

NUCAP Energy develops and manufactures engineered metal surfaces, called GRIPMetal, for a wide range of industries, including aerospace applications.

The company has used its years of industry experience to develop advanced, innovative technologies, working with various metal substrates, including stainless steel, aluminium, titanium, brass, and copper.

The original technology of surface modification has been used by NUCAP Industries in high-performance automotive brake systems for over 21 years. So far, the GripMetal technology has been used in more than a billion brake pads already used in cars and trucks around the globe successfully withstanding extreme temperatures and challenging environments.

Engineered surface materials for aerospace applications

NUCAP Energy offers engineered surface materials for use in the aerospace sector, significantly reducing the mass of cooling systems for electronic components and for climate control.

The company’s GRIPMetal-based solutions improve heat transfer efficiency in thermal applications, as well as provide unprecedented reinforcing capabilities in elements made of composite materials.

NUCAP Energy’s composite materials can simultaneously function as structural, active thermal, and electromagnetic radiation shielding components eliminating the requirement for using extra elements for each separate function lowering both the cost and mass of the final system. Especially the structural strength of GRIPMetal-based composites adds to superior ballistic properties of the material.

Patented non-subtractive processes for material enhancement

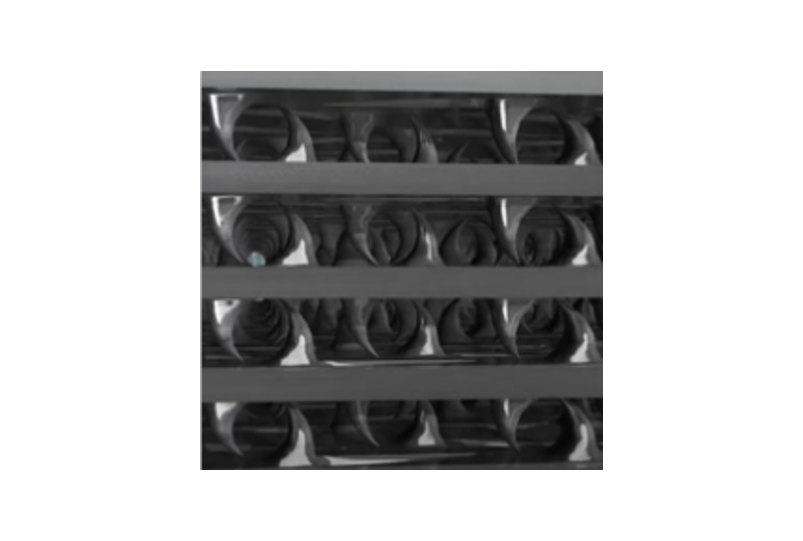

NUCAP’s GRIPMetal is fabricated using a patented non-subtractive process that enhances the metal surface forming rows of “Velcro-like” hooks. The hooks increase a metal’s surface area without adding to its weight. This means manufacturers can cut down the weight of their products without compromising on their structural and thermal performance.

The company’s cutting-edge processes can fabricate materials using any metal, shape, and hook geometry to meet a range of requirements, offering both single and double-sided enhancements.

Cooled and impact-resistant batteries

High-efficiency cooling systems are critical to keeping electric batteries and electronics running properly. Overheated batteries present a real threat to aerial vehicles, not only due to their ‘explosive’ properties but also due to inferior batteries’ capacity and service lifespan.

Additionally, structural strength of GRIPMetal-based composites can be used in the encapsulation of batteries and electronic components to add to the safety of an aircraft.

Use of engineered surface material provides manufacturers with more efficient options to draw heat away from batteries and electronic components to maximize their lifespan and performance.

Reliable and durable components for electronics

GRIPMetal-based CPU cooling components and cold plates (especially ones used with Insulated Gate Bipolar Transistors – IGBT), provide a substantial improvement of the heat exchange rate between electronic elements and cooling circuit. Efficient cooling capacity is not only boosting the performance and lifespan of any electronic device but also results in a higher computation speed. Additional benefit coming from the use of GRIPMetal material for electronic circuits is the ability of electromagnetic radiation shielding of vital components.

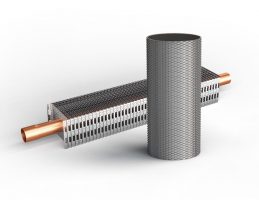

Heat exchangers for climate control applications

NUCAP Energy’s surface modification for heat exchangers can considerably improve the efficiency of the heat exchange process. Especially, in viscous media, such as oils, the heat transfer rate can be improved by nearly 100%, cutting costs and reducing the weight and size of the exchangers.

The company’s enhanced surface material can be used in practically any type of contemporary heat exchanger.

About NUCAP Energy

NUCAP Energy is a division of NUCAP Industries, the parent company of NRS Brakes and the owner of patented GRIPMetal technology. NUCAP was founded in 1994 and its manufacturing plants are located across Canada and the US. NUCAP Industries has a history of developing state-of-the-art manufacturing technology to improve surfaces of metallic materials.

NUCAP Energy manufactures GRIPMetal material and helps customers to develop or improve their existing products providing assistance of NUCAP’s engineering and R&D teams.