Sky Power GmbH, based in Bad Homburg, Germany, is the leading engine manufacturer of two-stroke internal combustion and Wankel engines, as well as for hybrid applications, for unmanned aerial systems (UAS). We develop and manufacture all unmanned aerial vehicle (UAV) engines in Germany and place particular emphasis on quality and reliability.

Sky Power offers a wide range of UAS propulsion solutions, including gasoline and heavy fuel engines, as well as hybrid systems that also use electrical energy for propulsion. The UAV engines are used in various aircraft platforms, such as fixed-wing aircraft, VTOLs, helicopters and multicopters.

Depending on requirements, the propulsions can be used as direct propulsions, in hybrid applications, as range extenders or to generate electricity. We are committed to investing in advanced technologies to enable our customers to design, build and operate reliable UAS systems.

We attach great importance to research and engine development to continuously set new standards in performance, reliability and efficiency. Our customers benefit from customised solutions tailored to their specific requirements. Sky Power also conducts in-house engine testing to ensure the highest quality standards.

With a highly skilled workforce and exceptional customer support, we aim to be the preferred global partner for reliable and professional UAS propulsion solutions and services in our industries. By continuously innovating and adapting to the growing needs of our users, we strive to always offer the best performance and value for money.

In 2024, Sky Power was recognised as a two-time winner at the Defence Technology Excellence Awards, underlining the company’s outstanding position in the industry. Every year we attend trade shows in the USA, Asia, Europe, the Middle East and Australia to showcase our latest engine developments and products to an international audience.

So we are also close to you!

The right solution for two-stroke and Wankel engines for your UAV requirements

Whether for ISR missions, industrial or commercial UAV applications ‒ Sky Power offers the optimal propulsion system for maximum efficiency, range and flexibility. Sky Power’s high-quality UAV engines are designed for maximum flexibility and for a wide range of application concepts in unmanned aerial systems (UAS). Whether as a direct propulsion, in hybrid solutions, as a range extender or as a generator for power generation ‒ our engines enable customised solutions for demanding UAV applications.

Possible applications for Sky Power propulsion systems:

- Direct propulsion ‒ Robust and powerful engines for UAVs that depend on a reliable combustion engine as the main propulsion.

- Hybrid solutions ‒ Combination of combustion engine and electric engine for optimised energy efficiency, longer range and reduced emissions.

- Range extender ‒ Efficient energy supply to extend the flight time of electrically powered UAVs.

- Generator operation ‒ Use of the engines to generate electricity for electric propulsion or on-board electronics ‒ ideal for energy-intensive applications.

For more information, please do not hesitate to contact us.

State-of-the-art technology for efficient UAV gas and HF-engines

Sky Power offers a choice between a classic carburettor or an electronic fuel injection system (EFI) for all Boxer engines. This flexibility makes it possible to adapt the propulsion precisely to the respective requirements and operating conditions.

Added value of fuel injection system

The use of an electronic fuel injection system offers numerous advantages that are directly reflected in greater efficiency, reliability and user-friendliness:

- Reduced fuel consumption

Thanks to the precise consideration of operating parameters, fuel consumption is minimised. This saves costs and significantly extends the operating times of your UAV platforms. - Electronically controlled fuel supply

The electronic control system ensures a constant, optimum fuel supply, regardless of external conditions. - Improved startability in cold temperatures

The EFI system has a reliable cold start function that ensures problem-free engines start even at low temperatures. - Automatic adjustment of the fuel mixture

The system automatically adjusts the fuel-air mixture to changing operating conditions, which optimises the performance and service life of the two-stroke engine. - Comprehensive PC monitoring options

All engine data can be monitored in real time via a PC. This enables detailed analysis and precise fault diagnosis. - Full control via the CAN bus

All relevant functions such as controlling the servomotors, analysing sensor values (analogue and digital), manual diagnostics and system updates can be controlled via the CAN bus. - Independence in any flight position

It is particularly important for the use of piston engines in UAVs to ensure that the fuel supply system functions independently of the position of the aircraft. This means that the full engine power remains available even when moving around the longitudinal or lateral axis ‒ an essential prerequisite for demanding flight manoeuvres and maximum reliability in use.

By choosing Sky Power, you benefit from state-of-the-art technology that makes your UAVs more efficient, reliable and powerful.

Added value of fuel carburettor system

Boxer, gas and HF engines with carburettor from Sky Power offer an ideal solution for UAV applications where robustness, ease of maintenance and economy are more important than maximum efficiency. It is ideal for long-term, reliable operations under stable flight conditions, especially in remote or infrastructurally weak regions.

Here are the most important added values:

- Proven technology with easy maintenance

Carburettor two-stroke engines are based on a long-established and robust technology. They are less complex than EFI systems (electronic fuel injection) and are therefore easier to maintain and repair, especially in remote areas. This saves time and costs during maintenance. - High reliability in stable operating environments

Since carburettors have no sensitive electronic components, they are less susceptible to environmental influences such as moisture or electromagnetic interference. - Cost savings when purchasing

Carburettor engines are generally less expensive to purchase than engines with electronic fuel injection. For UAV projects with a limited budget or for applications where maximum efficiency is not a priority, a carburettor boxer engine is an economically attractive option. - Robust performance with minimal electronics

By dispensing with complex electronic controls, the engine remains simple in design and mechanically robust. This is particularly advantageous in environments where electronic components could be affected by temperature fluctuations or vibrations. - Good performance with standard gasoline

Carburettor engines are often less sensitive to the quality of the fuel used and can be operated with standard gasoline. This facilitates operation in regions where high-quality fuel is difficult to obtain.

For more information about our engine portfolio, please do not hesitate to contact us.

Maximum safety and reliability thanks to Sky Power’s Twin-Spark Ignition

All UAV gas and HF engines for UAVs with a displacement of 55cm3 or more are supplied by Sky Power in a Twin-Spark (TS) version as standard. This innovative technology is characterised by two independently operating ignition systems that offer numerous advantages for the operation of UAVs.

Customers benefit from using the TS version as it enables a lower idle speed, which reduces the overall operating noise. This contributes not only to reduced background noise but also increases operational efficiency. Furthermore, TS technology significantly improves safety and operating stability for both single-cylinder and multi-cylinder engines. Even under demanding operating conditions, UAVs remain reliable in operation.

Should one of the two ignitions fail, the second, independently operating ignition ensures that the engine continues to run at a slightly reduced speed. This ensures that missions do not have to be interrupted, and the drone can be controlled safely. For customers, this means maximum operational safety and efficiency.

For this purpose, Sky Power has developed its own Twin-Spark Ignition as the ideal choice for all UAV operators who demand the highest reliability, maximum efficiency and safety. With its innovative twin spark technology, robust design and universal compatibility, this ignition system sets new standards in the UAV industry.

Sky Power’s Twin-Spark technology thus underlines its commitment to developing innovative solutions for the requirements of modern UAV applications of today and tomorrow.

For more information about Twin-Spark Ignitions, please do not hesitate to contact us.

Hybrid systems ‒ For greater range and longer flight times

Sky Power offers a wide range of innovative hybrid propulsion systems that have been specifically developed for use in UAVs. These systems combine the advantages of combustion engines and electric propulsions, enabling UAVs to achieve a greater range and longer flight times. The hybrid propulsion systems therefore represent a flexible and efficient solution that meets the requirements of a wide range of missions.

Thanks to the combination of combustion and electric engine technology, these hybrid systems enable longer flight times, greater ranges and the ability to safely transport heavier payloads. Especially when transporting heavy loads, hybrid solutions provide safe and reliable engine performance, even under demanding operating conditions.

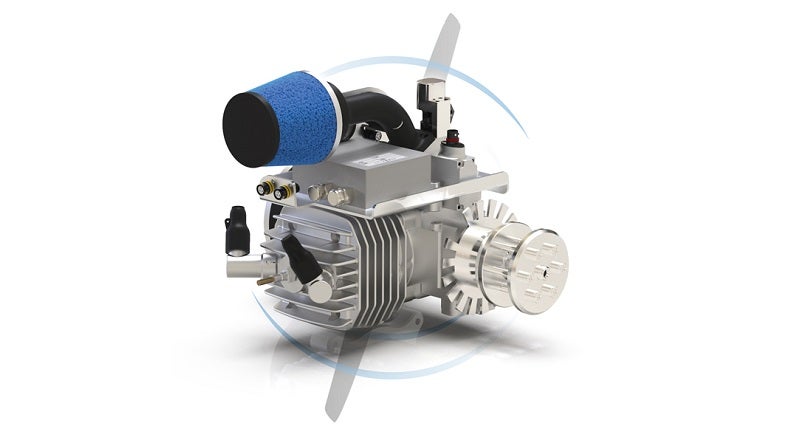

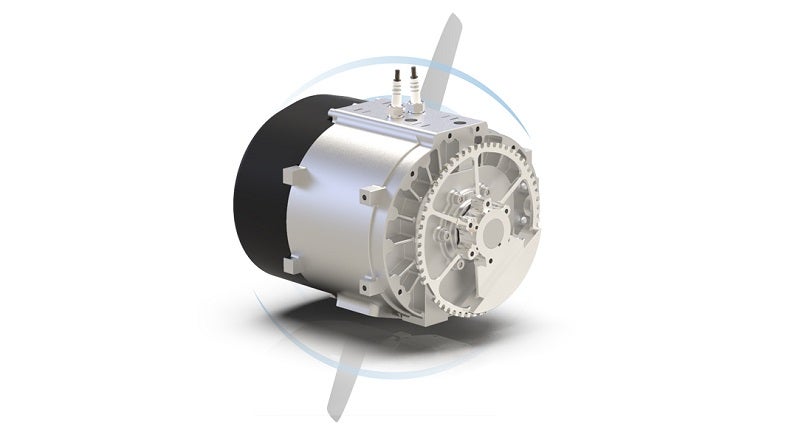

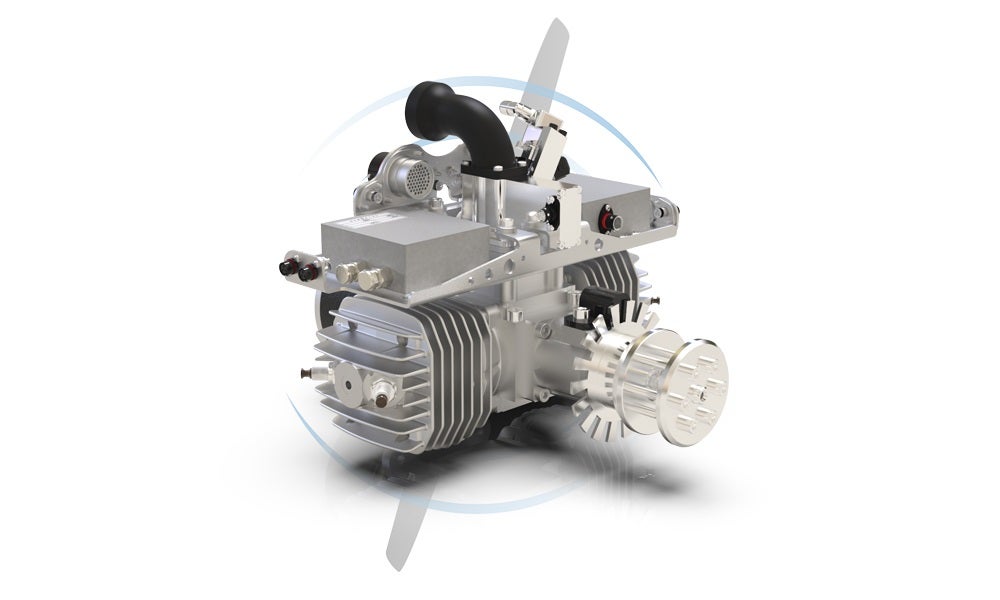

The hybrid propulsion systems consist of several key components that ensure optimum function and efficiency. A precise fuel injection system ensures accurate fuel delivery, which increases engine performance and reduces fuel consumption. The brushless DC generator efficiently converts mechanical energy into electrical energy to power the UAV’s electrical systems.

The SGC 352 starter-generator controller, a lightweight and compact control unit, regulates both the engine starting process and the generation of electrical energy. The integrated HKZ ignition system improves ignition performance and thus contributes to increased engine performance and reduced emissions. An additional cooling system ensures effective temperature regulation of the engine and generator, which ensures reliable operation under different environmental conditions.

The hybrid engines are designed for efficiency and compactness. The engine is integrated into a robust aluminium frame, with injection, control unit, temperature regulation and air supply mounted on the side. The UAV generator is located on the rear output shaft, making the hybrid system particularly space-saving. The cooling system is located above the engine and generator, providing the necessary fresh air supply and dissipating hot air.

Sky Power offers various hybrid configurations to meet different requirements. The SP-55 FI TS is a two-stroke engine, which was specially developed for smaller UAVs and impresses with its compactness and efficiency. The SP-180 SRE hybrid, a powerful Wankel engine, is available for more power-intensive applications. Another variant is the SP-180 HF SRE, which has been optimised for operation with heavy fuel and is therefore ideal for ISR missions.

For more information about hybrid systems, please do not hesitate to contact us.

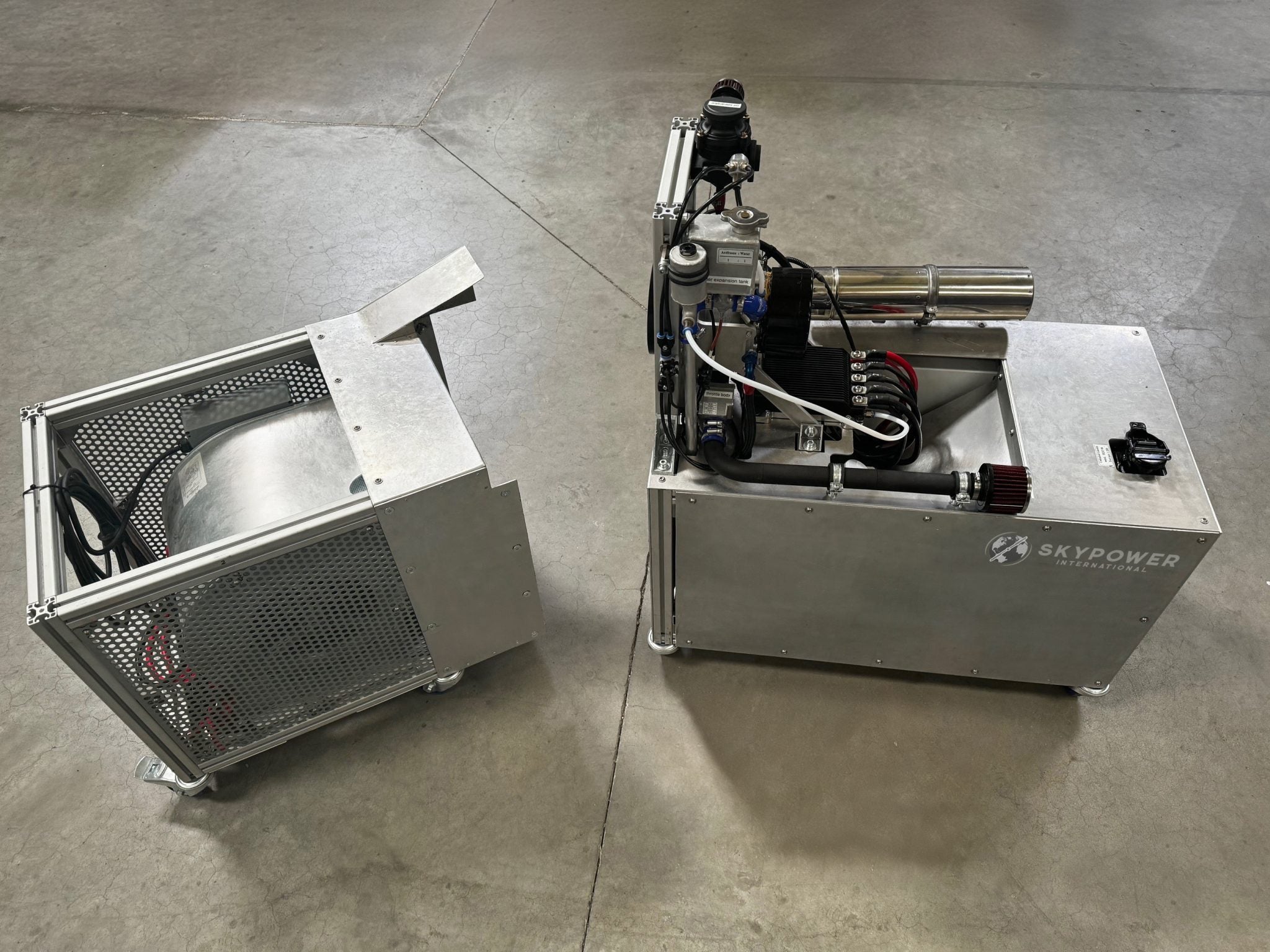

Break-in and routine test and mobile test stands

Sky Power International offers comprehensive testing capabilities for their UAV engines to analyse their performance and condition. Our tests are specifically designed to perform both routine checks and detailed failure analysis.

- Break-in test for Sky Power engines

A break-in test is an essential running-in process that Sky Power carries out for its UAV engines. The engine is operated under controlled conditions to ensure that the moving parts are optimally tuned.

At Sky Power, the break-in test is carried out on specially equipped test benches, where each engine is subjected to a defined load and runtime sequence. This ensures that the engine reaches its maximum performance and offers a high level of operational reliability. This running-in process not only extends the service life of the engines but also ensures their reliability under real operating conditions. - Routine test on the engine test bench

To ensure the performance and functionality of the engine, every engine is tested on our test bench before delivery. - Our test procedures for failure analysis

Engine tests for failure analysis: depending on the condition of the engine, we carry out tests to find faults. If necessary, we also dismantle specific engine components for more detailed examinations. Cylinders, pistons and piston rings are checked for wear and damage. After a thorough inspection, we carry out any necessary maintenance work.

Sky Power is committed to the highest quality standards and thoroughly tests each engine to meet the requirements of demanding UAV applications. If you need more information about our testing procedures, please contact us. - Mobile test stand for Wankel engines

Sky Power’s SRE180 test stand provides a test solution for the SP-180. Due to the compact design the whole test stand is well suited for portable use. Test stands help to save costs by reducing expensive flight tests and identifying potential on the ground. This lowers development and operating costs and contributes to improving the overall cost-effectiveness of a UAV project. Another major advantage of engine test stands is the ability to carry out reproducible tests. Engineers can carry out the same tests several times to ensure consistency and reliability of the results.

For more information about our test possibilities, do not hesitate to contact us.