Simpro specialises in electronics manufacturing services (EMS) for defence applications.

Simpro specialises in electronics manufacturing services (EMS) for defence applications.

We offer our customers a comprehensive end-to-end portfolio, with services ranging from design and development to direct product distribution.

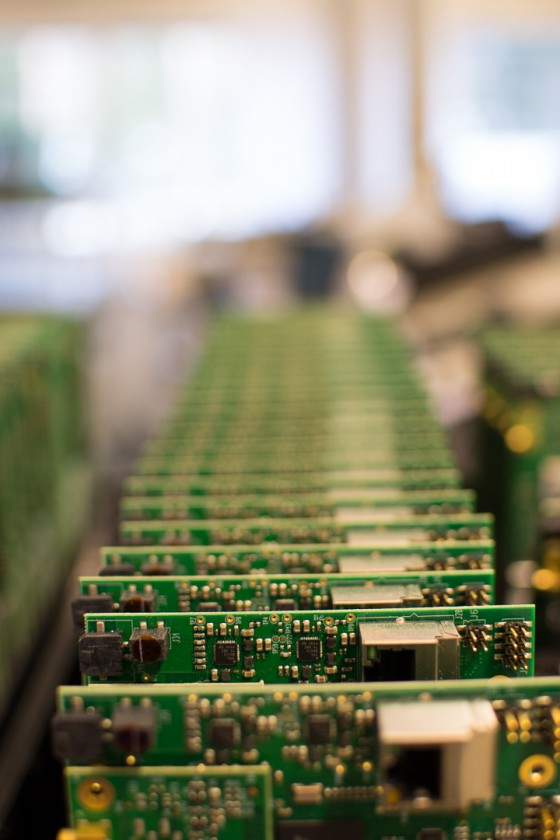

Electronic surface mount technology production

Simpro is experienced in the production of surface mount components. Our range comprises everything from prototypes to large series, and production lines that can handle components measuring up to 90mm x 30mm.

Our two independent assembly lines are optimised for low-to-medium volume production, with the latest installed near the end of 2011. Each has a total theoretical assembly rate (IPC-9850) of 150,000 components an hour.

Simpro also has two automatic optical inspection (AOI) machines, one of which is integrated into the surface-mount technology (SMT) assembly line, while the other is a standalone station. AOI is used to enable correction and detection prior to soldering, as well as the inspection of the soldered printed circuit assembly (PCA). We also use nitrogen when conducting selective and wave soldering, as well as re-flow soldering upon request.

Simpro provides IPC Class 3 production according to:

- Workmanship

- Workmanship and documentation

- Workmanship, documentation and traceability

All our operators are J-STD 001 IPC-A Class 3 certified.

Selective conformal coating systems for defence applications

Simpro’s new selective conformal coating system can be used on the PCA, as well as for automatic glue and potting dispensing processes.

The system guarantees a consistently high level of quality and simplified process, as well as improved operator health and safety.

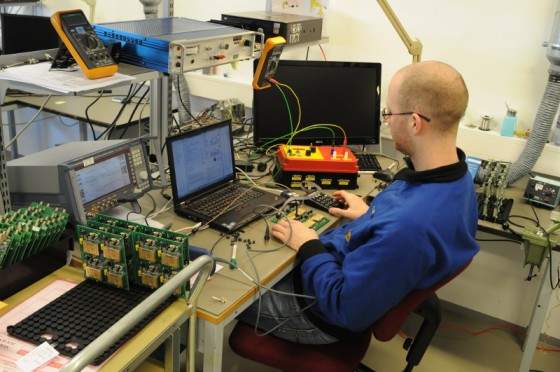

Automated test development services

Simpro’s test department offers extensive experience within the area of electrical component competency, including data logging, error detection and environmental stress screening (ESS).

It performs test development, product adjustment / tuning / calibration and enhanced troubleshooting, as well as enhanced instrumentation for radio frequency (RF) testing. It additionally deploys LabView, TestStand and Boundary Scan for the efficient and automated testing of complex products. The testing is purposely automated so that operators can test the product during various production stages, enabling consistency, quicker detection of potential errors, improved reporting, and rapid implementation.

Through collaborative test development with industrialisation and development, our customers can be assured of automated testing ready for the first production batch, increased product knowledge before it enters the production stage, design for testing (DFT) analysis potential with Boundary Scan electronics assistance and high-quality product documentation through test development procedures and AutoCAD drawings. These processes ensure clients of prepared systems that can endure high-mix and low-volume production for a range of locations.

Simpro’s new test system, known as WATS, is a database system that processes test data, reports, data analysis, production statistics and quality monitoring. It also is TestStand and LabVIEW ready, as well as enterprise resource planning (ERP) integrated. Customers can use WATS to detect inconsistencies and bottlenecks, contribute to quality monitoring, view resource usage to include in production planning, provide traceability, and be included in a customer’s programming language for microcomputers (PLM).

Environmental stress screening for ongoing production

Simpro provides environmental stress screening (ESS) for either ongoing production or alongside testing and qualification of new products.

ESS exposes a product to environmental stresses to identify and remove latent defects to ensure higher reliability and a longer service life. The process varies from checking an electronic system before shipment, to the application of major environmental profiles such as extreme temperature and vibration cycles.

Screening advantages are dependent on the manufacturing process maturity, since more mature processes are anticipated to bring about fewer defects. The failure rate of a system population is estimated to be up to four times higher at initial deployment than after a year, meaning if no ESS is carried out, it will take up to one year for the population to reach the assumed steady state observed during the useful life duration.

Simpro offers ESS tests for:

- Production ESS testing as part of the ongoing production

- Q1 and Q2 qualification tests as part of the preparation before a formal qualification of the product

- Development ESS tests during the development stages

We also supply a full ESS programme, including documentation, test development, and test planning and execution.

About Simpro

Based in Norway, Simpro is a leading EMS manufacturer of hi-tech electronic and electromechanical components for adverse environments. We were first established in 1990 as a start-up business, which has now grown to comprise a team of more than 500.

Simpro supplies services to a range of customers in various industries, including defence, offshore and medical.