Kanfit is a built to spec / print aerospace engineering and manufacturing company offering a full-service turnkey solution to meet all user requirements, from 3D models to prototypes to serial production of aerostructures for civil and military aircraft.

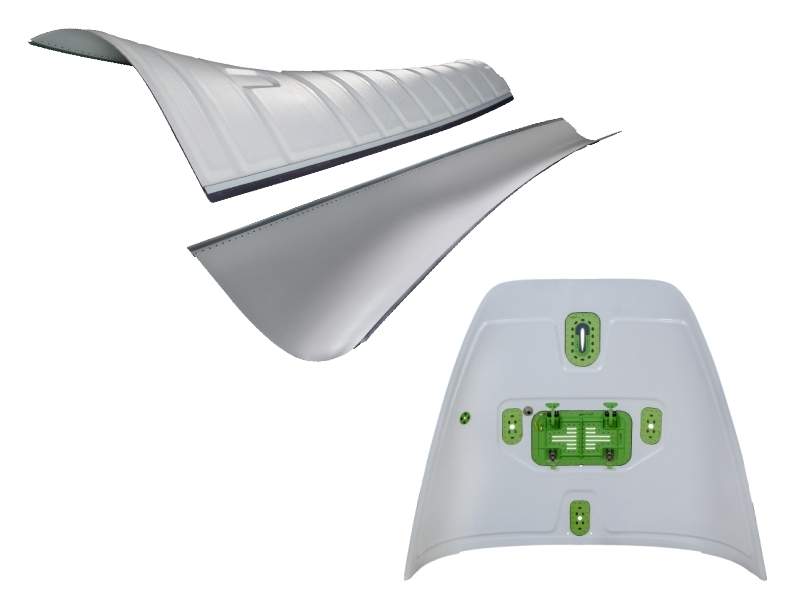

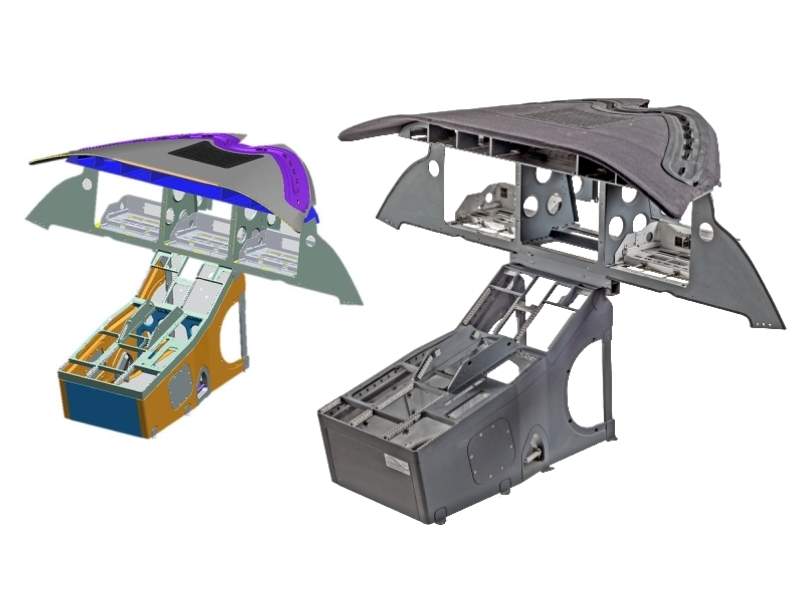

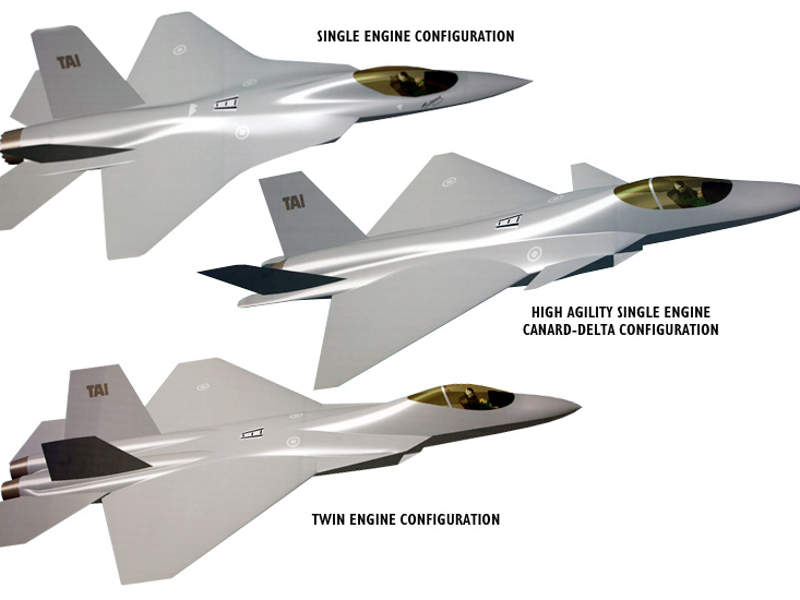

Kanfit manufactures and integrates primary and detailed parts, subassemblies and Fit & Fly assemblies made from composite materials, in addition to sheet and block metals for military and commercial aviation jets, rotorcrafts such as helicopters, and unmanned aerial vehicles (UAVs).

Available aerostructures manufactured by Kanfit include flight deck and cockpit structures, avionics and main landing gear doors, wing to belly and wing to body fairings, chaff and flare dispenser magazines, missile and bomb parts, airborne and space antennas, satellite dishes and satellite (SATCOM) radar dome (radomes).

Components for commercial and military aircraft and UAVs

Kanfit utilises the latest processes to manufacture composite aero structures, including autoclave, Resin Transfer Moulding (RTM), Liquid Resin Infusion (LRI), prepregs in oven and vacuum and wet lay-ups.

For metal aircraft structures, Kanfit uses mainly aluminium sheet metal, but also block and extrusion and various types of alloys such as steel, copper, etc.

We also undertake machining, forming, heat treatment, chemical coatings, finishing and assembly.

Kanfit additionally produces aerostructures made from Titanium Alloy Ti64 using 3D additive manufacturing, as well as develops other production processes such as Automated Fibre Placement (AFP) and robotic filament winding of closed frames.

Durable chaff and flare dispenser magazines for airforce applications

Kanfit manufactures composite chaff and flare magazines using RTM technology for improved magazine accuracy, extended durability and enhanced reproducibility. Using this technology, the company is able to manufacture magazines that are significantly lighter in weight than those made from metals.

Kanfit’s chaff and flare magazines are produced in a single injection process, with the metallic inserts embedded into the component and in one piece. This lack of seams ensures zero failure points, and components are delivered ready-to-install directly to the customer.

Kanfit has manufactured more than 8,000 chaff and flare magazines for use by air forces worldwide. According to customer feedback, the company’s chaff and flare magazines provide 100% reliability, the longest lifecycle and offer the highest level of performance on aircraft.

Test results for ALE-47 CMDS magazines, in which ten full rounds of 5×6 flares were sequentially fired, show that Kanfit’s chaff and flare magazines remained as durable and robust as initial firing. All products comply with US military testing standards MIL-STD-810, EMI/RFI and MIL-STD-461F.

By combining our expertise in materials and engineering, Kanfit is able to meet specific operational requirements and specifications for manufacturing chaff, flare and decoy systems. The company also manufactures breech plates and magazine housings (bucket) and components for anti-missile air defence systems and radomes.

SATCOM radomes and satellite dishes for the defence sector

Among the radomes manufactured by Kanfit is a 3.5m-long radome for SATCOM applications made from quartz epoxy prepreg materials.

In comparison to radomes manufactured using out-of-autoclave technology, this radome was manufactured at the company’s in-house autoclave facility. Designed for civil and military aircraft, it underwent comprehensive mechanical and physical testing in Kanfit’s in-house laboratory.

The company also manufactured several complete sets of dish and gores for a prominent aerospace company, with parts in serial production. The carbon-fibre central satellite dish and hybrid gore manufactured by Kanfit have been in space since 2013.

Industrial 3D printing of aerospace components

3D additive manufacturing is the latest technology to be introduced at Kanfit for the production of high-quality metal parts for the aerospace and medical industries.

This flexible mode of manufacturing enables the company to create tooling inserts, complex prototypes and customised parts and serial aircraft products directly from computer-aided design (CAD) data.

Advanced composite and metal structures for the aerospace industry

Established in 1986, Kanfit is a major subcontractor to global aerospace industry leaders, including Israel Aerospace Industries (IAI), Israel Air Force, Israel Ministry of Defense, Elbit Systems, Rafael, BAE Systems, Senior Aerospace), Extant Aerospace, Triumph Aerostructures, Spirit AeroSystems, BIRD Aerosystems, and others.

Kanfit is AS9100C certified and National Aerospace and Defense Contractors Accreditation Program (Nadcap) accredited for composites, heat treatment, and chemical processing. The company is certified by Boeing for heat treatment and chemical processing, and by United Technologies Corporation Aerospace Systems (UTAS) for heat treatment.