TRICOR Systems, Inc. provides award-winning electronic contract manufacturing to the aerospace and defense sectors.

TRICOR offers a wide variety of services ranging from short-run prototypes to full production. TRICOR excels at complete, fully tested box builds, cables, harnesses, circuit card assemblies and build to print. Custom electronic equipment is our specialty. Value added services include: an engineering staff to support electro-mechanical & electro-optical equipment from concept to production, hardware and software design, qualification testing and PCB layout from through-hole to surface-mount.

The company has established a reputation for its high quality and on time delivery. TRICOR received the Boeing Performance Excellence Award for seven years consecutively by providing 100% quality and delivery. Also, TRICOR has been nominated twice for Boeing Supplier of the Year Award.

Contract manufacturing services for the aerospace and defense industry

TRICOR is an AS 9100D certified, ISO 9001:2015 and International Traffic in Arms Regulations (ITAR) registered manufacturer with over 40 years of experience in providing high-quality products and services to clients in the defense sector.

TRICOR’s contract manufacturing capability ranges from high-mix low-volume to large production quantities.

Experienced engineering support for projects

TRICOR’s experience in assessing documentation during the quotation process means customers can be made aware of any issues before the project begins.

We have a highly skilled in-house engineering team that can streamline product updates, reduce costs and save time by recommending part substitutions for obsolescence.

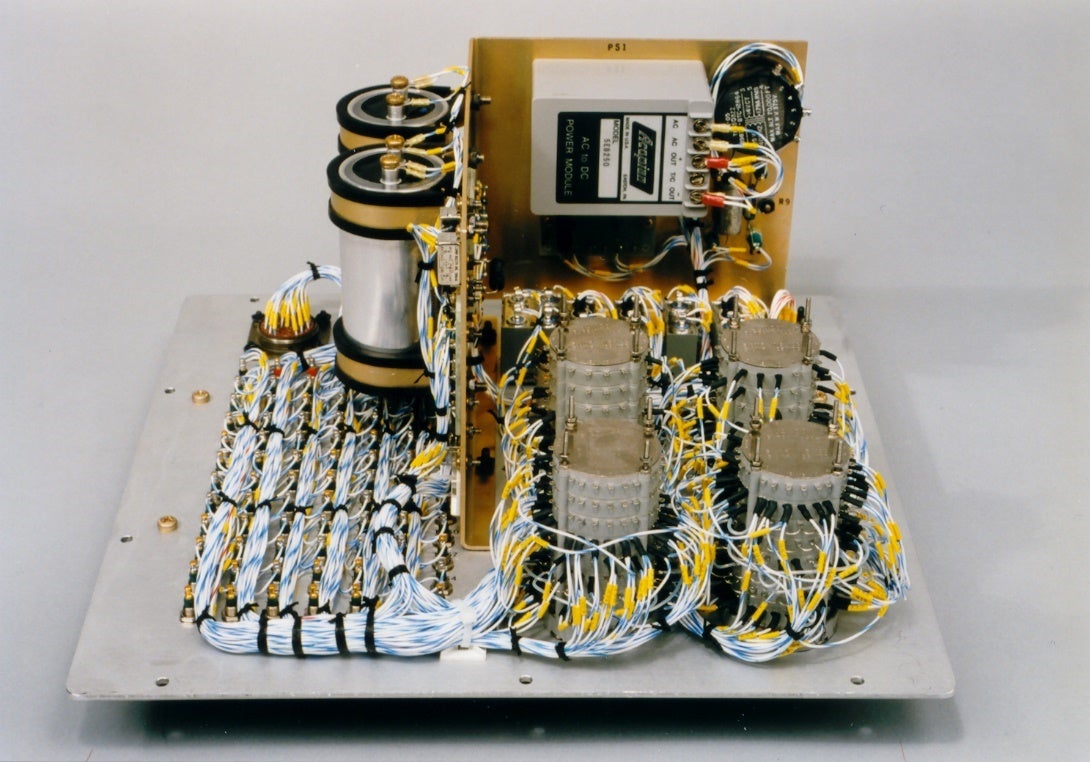

Simulators and electrical systems for aerospace & military applications

TRICOR’s manufacturing capabilities include ground support test systems, custom illumination systems, and simulators for the aerospace and defense sectors.

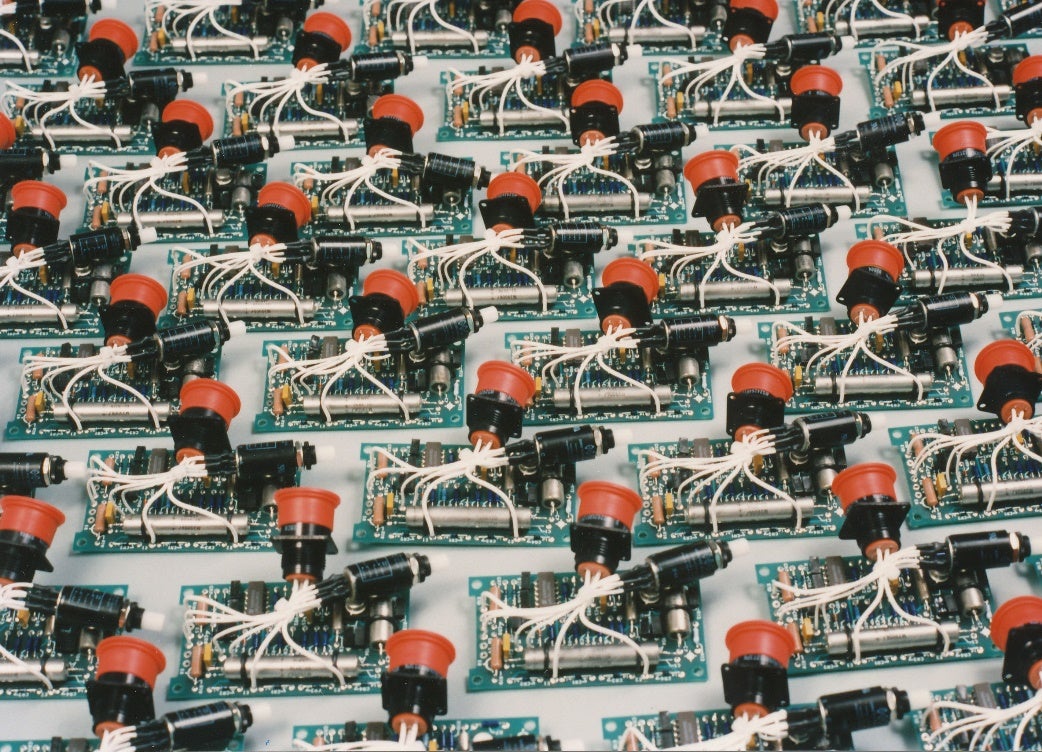

Our manufacturing expertise also extends to electronic systems, surface mount technology (SMT), cables, and circuit cards, as well as electro-optical and mechanical devices.

Industry-certified product assemblers for aerospace products

Half of TRICOR’s electronic manufacturing facility is devoted to product assembly, fabrication, integration and testing. TRICOR maintains a variety of equipment on site including a surface mount line (SMT) for board manufacturing, wire cutters & stripping machines, wire braiding machine, conformal coating area and numerous scopes & testers to carryout acceptance test procedures (ATP).

TRICOR’s assemblers are trained and certified to IPC J-STD-001 soldering and workmanship standards and have extensive experience in the aerospace and defense sectors.

TRICOR’s quality control inspectors ensure all products meet the standards required by our customers.

First article inspection (FAI)

TRICOR places a strong emphasis on performance, reliability and quality during its electronic contract manufacturing process.

TRICOR has years of experience performing First Article Inspections (FAI) as required by contract.

Please contact TRICOR to learn more about our services.