Cranfield Aerospace Solutions (CAeS) is involved in the design, development and manufacture of modifications, maintenance, environmental characterisation and rapid prototyping of new aerospace concepts.

Our solutions are established on fixed, rotary wing and unmanned air systems, working with multiple operators such as aerospace Tier 1 & 2 companies. These are supported by the European Aviation Safety Agency (EASA), Civil Aviation Authority (CAA) and Ministry of Defence (MoD) approvals for design, build and certification processes, as well as composites, avionics and systems integration, performance and weapons clearance.

In-flight simulation for military high-speed aircraft

CAeS produces G-Cueing (Motion-Cueing) in-flight simulator seats that create the sensation of sustained G-forces, providing fully immersive experiences. These are also used in our motorsport simulation systems.

Our G-Cueing (Motion-Cueing) portfolio provides sophisticated G-cueing for military high-speed aircraft such as the F-18, commercial aircraft, helicopters and a driving simulation for motorsport, including F1.

The sensations of sustained G-forces are primary cues for total immersion in the simulation. CAeS also provides sensory stimuli while moving through G-force inducing manoeuvres.

G-Cueing simulations can replace or enhance motion platforms and are easily deployable into concept mock-ups and in-theatre training.

Aerospace design services for complex modifications

In-house competencies include aerodynamic and mechanical design, stress analysis, certification and avionics.

With our EASA and MOD approvals, CAeS, designs, builds, tests and flies complex aircraft modifications on both manned aircraft and UAVs. Aerodynamic design, mechanical design, avionics, stress analysis, flutter analysis, and certification expertise for current aircraft, future systems and historic aircraft are all available.

A recent design for hard-points on the King Air 350i to support 120kg per wing has been completed, which included flutter analysis of the wing / aircraft and ground vibration testing (GVT) testing of the wing.

We are an EASA Design Organisation Approval (DOA – Part 21J), and EASA Production Organisation Approval (POA – Part 21G), and Part-145 approved company.

Safety and suitability for aircraft weapon systems

CAeS provides services for the safety clearance and carriage of weapon systems for land, sea and air vehicles using environmental data gathering instrumentation for vibration, shock, strain, temperature and pressure.

Structural characterisations support the qualification, role change and platform life extension through modal analysis and finite element modelling. Tailored test severities are generated and sensors with multiple data channels enable accurate data collection and analysis. Projects include the Typhoon, Tornado and F-35, as well as aircraft from international air forces.

Rapid prototyping and concept studies for flight testing

CAeS offers innovative solutions in concept development and evaluation to better utilise flight test methods. To achieve this, the company incorporates concepts of operation, technology road-mapping, characterisation on environment and controllability of blended wing body, as well as developing techniques from wind tunnels to large-scale testing.

Examples include a blended wing concept design, the X-48B, a UAV X-Plane, to test aerodynamic characteristics. CAeS designed the aircraft systems and ground station for piloting the vehicle. Another concept was supporting E-Fan 4 for hybrid / electric propulsion concept development.

High-quality manufacture and maintenance services

CAeS provides quality maintenance under our Part 145 Maintenance, Part M Continuing Airworthiness and A8-23 Approvals, covering all necessary maintenance services to support private, business or commercial customers.

We also efficiently and effectively provide approved technical solutions for ongoing maintenance and support.

Air and ground operations for safe aircraft manoeuvre

Runway and helideck friction testing ensures the safety of aircraft manoeuvring at airports and supports the removal of hazardous helideck landing nets. Projects include water ingestion trials at our specially constructed facility and aircraft noise testing.

Detailed assessment reports contain levels of conformance, recommendations, friction contour maps and individual run profiles.

CAeS uses CAA-approved friction testing equipment.

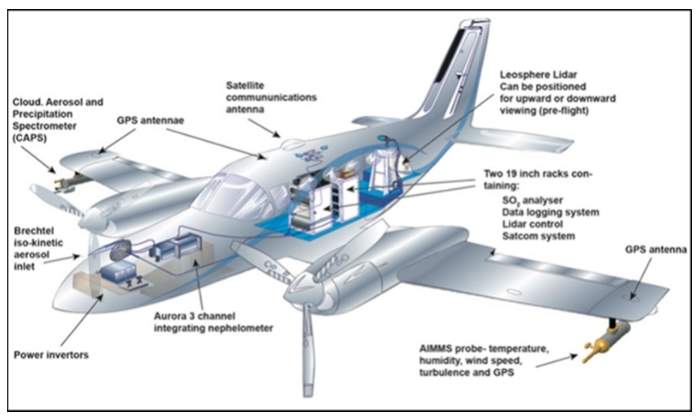

Special-purpose aircraft for system simulation

The Cranfield Aerospace Special Purpose Aircraft (CASPA) Cessna 421C provides a highly flexible service for research, equipment validation and certification, system simulation, and multi-aircraft or role-modelling operations.

CASPA is equipped with standard racks to allow customer specific equipment and can carry five additional people during flight test operations.

About Cranfield Aerospace Solutions

Established as the Cranfield College of Aeronautics in 1946, CAeS is a wholly owned subsidiary of Cranfield University and an EASA Part-21 and Part-145 approved company. Using our strong research and development links with the university, we also convert innovative research into market-leading technologies and services.

We contribute to research, concept development, trials and support in the field of unmanned air systems (UAS). Our experience enables flexibility through design, manufacture and testing and we have been involved in a number of worldwide concept projects and operational UAS.

CAeS covers design, analysis, manufacture, modification and servicing on piston engines, turboprop and jet aircraft, as well as metal, wood and composite airframes.

The company supports a number of Britain’s most iconic historic aircraft and has acted as design adviser and independent technical evaluator for the Battle of Britain memorial flight since 1985. We have also supported the Vulcan to the Sky Trust, the Royal Navy Historic Flight and Army Historic Aircraft Flight.