US-based Lockheed Martin has been awarded a $172m modification contract by the Naval Air Systems Command to increase manufacturing capacity for the F-35 aircraft.

The contract will also provide special test and tooling equipment, material modification kits, and support for removing life limits, correcting deficiencies, and retrofitting aircraft to incorporate next-generation distributed aperture system (DAS) hardware, and associated power and thermal management system modifications.

The F-35 programme has numerous international partners that are involved across different levels. These include eight partners, namely the UK, Denmark, Canada, the Netherlands, Norway, Italy, Turkey, and Australia.

The program has political, tactical, and strategic value, providing Nato states with advanced and capable aircraft while extending the influence of the US defence market through a lucrative programme for Lockheed Martin, according to GlobalData’s US Defense Market 2022-2027.

Lockheed Martin‘s modifications will be implemented on F-35 aircraft for the Air Force, Marine Corps, and Navy, as well as foreign military sales (FMS) customers, and non-US Department of Defense (DoD) participants. Lockheed Martin will carry out the work in Fort Worth, Texas, which is expected to be completed in December 2030.

According to GlobalData’s The Global Military Fixed Wing Aircraft Market 2022-2032 report, combat aircraft is the largest segment in the market. The US is expected to be the largest spender on combat aircraft procurement, with $211.4bn between 2022 and 2032.

Lockheed Martin’s F-35 is a fifth-generation stealth fighter aircraft designed for multiple roles, including air superiority, ground attack, and intelligence gathering. The DAS enhances situational awareness for pilots by providing a 360° view of the surrounding environment.

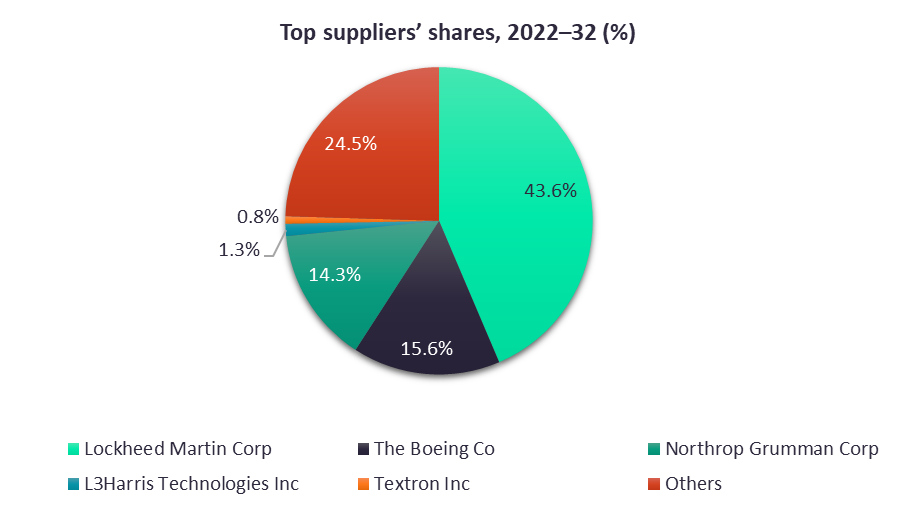

Lockheed Martin will account for a 43.6% share of North America’s military fixed-wing aircraft market with an estimated revenue of $134bn over 2022–2032, according to GlobalData.

The company has made significant investments in improving the manufacturing process to ensure the timely delivery of the aircraft to its customers.