In addition to High Strength Steel products offered to the heavy industry and large machinery industries, the SSAB portfolio comprises high-end steel plates and other products that are custom designed for the building industry.

The wide range of SSAB steels for construction applications is aligned with SSAB vision, calling for ‘Lighter Yet Stronger’ structures. Adopting SSAB steels in buildings can drastically reduce material consumption and carbon dioxide emissions, thereby supporting sustainability and conservation of ecosystems.

SSAB is taking the lead by developing steels intended for a variety of building styles and usages. The award-winning SSAB steels is an additional mark of their unique quality. SSAB construction steels can combine one or more of the following characteristics – ballistic protection/corrosion resistance/environmentally friendly coating and many other aspects.

Here we list a few of the more notable building and construction applications over the last few years where SSAB steels were used:

Embassy of Sweden, USA

The Embassy of Sweden is located on the second floor of a unique building known as the House of Sweden in Washington DC. Its facilities include offices, an exhibition venue, a business centre and corporate offices. It was designed by Swedish architect Gert Wingård and won several local and international awards. King Carl Gustaf XVI of Sweden inaugurated the building in 2006.

With its modern looks, the House of Sweden is intended to reflect Swedish simplicity, transparency and light atmosphere. Its scenery gives it a magical impression of calmly floating along Washington’s Potomac River, surrounded by green trees in its landscaped gardens.

Behind this peaceful and relaxing ambiance, the Swedish embassy (and the entire House of Sweden) is highly (and unnoticeably) protected by various grades and thicknesses of Armox® plates. This ultra-tough steel from SSAB is installed in the building’s walls, doors and other areas. Armox® contributes to making the House of Sweden a very safe and secure place for workers, residents and visitors.

STIGA Sports Arena, Sweden

This modern, environmentally sustainable complex was opened in 2017, as a centre for sports, events and concerts. It has been awarded the Swedish Green Building Council’s Gold Certificate for its use of low environmental impact construction materials, and that it has low energy consumption when in use.

Three grades of SSAB steel were used to construct the roof trusses for the main arena, using cold-formed rectangular and square hollow tubes. Domex® Tube Double Grade was used in two strengths, S355J2H and S420MH, while the final was made from SSAB Strenx® Tube S700MC.

The profile and tensile strength of SSAB’s steel allowed very long-span roof trusses to provide the large open plan areas that are necessary for unrestricted viewing by spectators.

SSAB GreenCoat® steel for building envelopes and rainwater systems

SSAB actively tracks and anticipates future changes in environmental, safety and regulations. As the name implies, GreenCoat® steel from SSAB features a large variety of bio-based colours and anti-corrosion coatings. GreenCoat® steel complies with various sustainable rules and programs as LEED (Leadership in Energy and Environmental Design), BREEAM (Building Research Establishment’s Environmental Assessment Method), REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and others.

That makes it very attractive for building roofs, facades, general cladding, and external pipes as it gives the building more credits in the rating system and evaluation by standardisation institutes and local authorities. GreenCoat® also achieves the highest and toughest safety levels in the way it is used in food industry applications such as freezers and storage spaces.

Prize-winning projects, using GreenCoat® continue to pop up, such as:

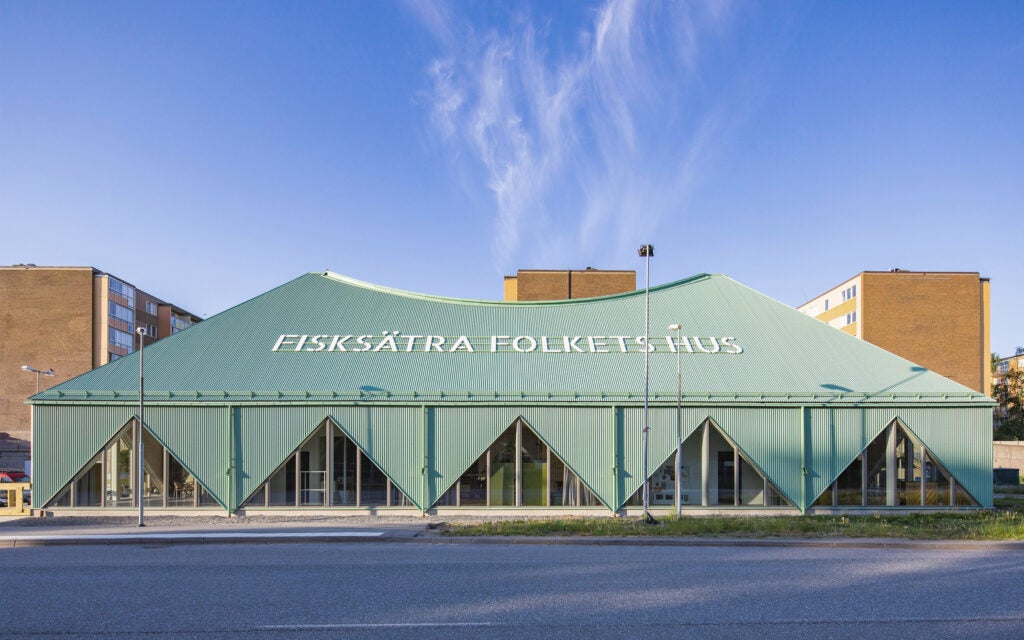

‘Fisksätra Folkets Hus’ (a traditional tent). This structure was designed by Thomas Sandell of Sandellsandberg Arkitekter and constructed using GreenCoat® Pro BT colour coated steel solutions in a warm Silver Fir Green shade, produced using Swedish rapeseed oil instead of fossil-based oils to make the coating. This patented coating technology is unique in the market.

This design and construction won the prestigious Swedish Design Award, ‘Design-S 2020’, in the ‘Architecture’ category. It features a striking 20-metre skylight, triangular windows and a minimalist, yet inviting interior.

Ruukki Construction first to supply fossil-free steel building products

A subsidiary of SSAB Group, Ruukki is committed to offering its customers a wide range of fossil-free steel building products. These will be designed and manufactured using SSAB’s HYBRIT technology, and it forecasts that they will be bringing final products to market in 2026. Until then, together with continuing large investments in research and development in the field, Ruukki will partner with selected customers for pilot projects to test a variety of products and applications.

The global drive for sustainable practices and products, Ruukki’s plans are to have the most sustainable offering and operations, to help themselves and their customers achieve a big reduction in their carbon emissions. It projects that fossil-free steel will help reduce the carbon footprint for these products by around 85%. A further 30% reduction may be achieved by intensive research into energy-efficient envelope solutions. In Ruukki’s own operations, it aims to further reduce carbon emissions by 25% by 2026.

And with its continuing research and development in HYBRIT technology, SSAB aims to bring fossil-free steel to the global market in 2026. (HYBRIT is a joint venture initiative of SSAB, LKAB and Vattenfall.)

SSAB and Peab collaborate on fossil-free, high-quality steel

Another large construction company from Sweden, Peab has selected SSAB’s fossil-free steel, produced using the HYBRIT process, in their construction projects from 2026 onward.

The companies will jointly analyse future possibilities for how fossil-free steel can help the construction industry aim for more sustainable building projects in the future, in Sweden and around the world.

“We are pleased to welcome Peab as a partner for our fossil-free steel products,” said Martin Lindqvist, President and CEO of SSAB. “Through fossil-free steel collaboration, we contribute to strengthening our customers’ competitiveness and to reducing their carbon footprint. Together, we also strengthen the position for fossil-free steel in the construction industry, while also helping to reduce global carbon dioxide emissions.”

Peab has ambitious climate and environmental targets, “And this is an important step for us to reach climate neutrality by 2045. Access to fossil-free steel will increase our opportunities. Our collaboration on fossil-free steel is also a natural development of the good relation Peab and SSAB already have in terms of climate efficiency,” said Jesper Göransson, President and CEO of Peab.

For more information: Please visit https://www.ssab.com/